Safety

Safety reigns as our foremost priority across every product and service we provide

Highest Safety

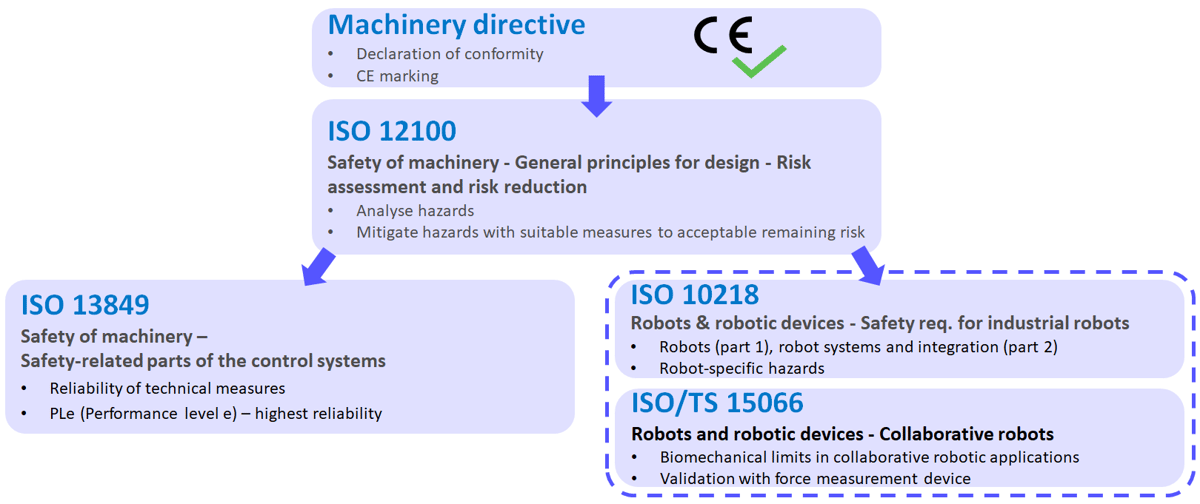

AIRSKIN is designed to ensure that your robot application meets ISO 10218 (ISO/TS 15066) standards.

Decrease Cycletime

Upgrade your industrial robots with AIRSKIN. Collaborative movement speeds significantly faster than traditional cobots (up to 2 m/s).

Increase ROI

Save costs and increase the ROI of production cells. Add AIRSKIN to your current industrial robot, allowing advanced levels of safety with the programming interface you are already familiar with.

AIRSKIN sets the industry standard for safety, empowering productive automation without the need for fences, all while prioritizing the safety of workers around industrial robots.

AIRSKIN detects all collisions with the robot and associated tooling (free-space, clamping, and shearing) in a maximum of 8ms, bringing the robot to an immediate halt.

AIRSKIN guarantees the highest safety standards, ensuring complete protection for both your workforce and workplace. With certifications according to EN/ISO 13849-1 (PL e / Cat. 3) and EN/IEC 62061 (SIL 3), AIRSKIN ensures your robot application complies with ISO 10218 (ISO/TS 15066) standards.

With just 5 N of force needed to activate, AIRSKIN's soft, pads effectively dampen collisions, absorb energy, and prevent high local pressures, keeping both your workforce and equipment safe inside the biomechanical limits of ISO/TS 15066.

More about AIRSKIN technology

Discover the benefits of AIRSKIN for your fenceless production. Thanks to its advanced energy absorption properties, AIRSKIN allows for an impressive increase in permissible speeds up to 6 times compared to cobots on the market.

Key Advantages:

- Unmatched Safety: For clamping collisions, AIRSKIN ensures safety by factoring in the robot’s stopping distance relative to the pad thickness, and by using ISO 10218 (ISO/TS 15066) compliant measurement devices.

- Streamlined Safety Assessments: Simplify your safety assessment process with our safety documentation, available for a range of AIRSKIN robots.

AIRSKIN is a tactile sensor that ensures uninterrupted workflow on your production floor. Unlike traditional systems, AIRSKIN does not halt operations until collision occurs. This means your cycle time remains unaffected even when workers are in close proximity to the robot.

- Continuous Operation: With AIRSKIN, your production line keeps moving smoothly, eliminating downtime and maximizing productivity.

- Safety Assurance: Experience peace of mind knowing that AIRSKIN enables safe collisions, preventing damage or harm in your facility.

- Efficiency Boost: By seamlessly integrating into your operations, AIRSKIN optimizes efficiency without sacrificing safety.

Don't let safety concerns slow you down. Embrace AIRSKIN and elevate your production floor to new heights of safety and efficiency!

Download the Fenceless Experts flyer

Download the technical specifications

Discuss your automation requirements with us

Frequently asked questions about safety with AIRSKIN

-

AIRSKIN is certified as a safety sensor in Performance Level e, Category 3, according to EN ISO 13849-1 and SIL 3 according to EN / IEC 62061.

◦ PFHd [1/h] with up to 15 pads: <= 1.38e-8

◦ MTTFd: 154 Years, DC = 99%For more specifications about AIRSKIN, download the full datasheet and the certifications from our request technical data page.

-

◦ EN ISO 13849‐1 PLe / Cat 3

◦ EN/IEC 62061 SIL 3

◦ UL 1740:2018

◦ ANSI/RIA R15.06‐2012

◦ CAN/CSA‐Z434‐14 + GI1

◦ TUV Austria: TÜV‐A‐MHF/MG/17‐00411

◦ TUV Rheinland: CU 72192170 0001

-

YES, AIRSKIN complies with UL 1740:2018, ANSI/RIA R15.06-2012, CAN/CSA-Z434-14 + GI1 according to TÜV Rheinland