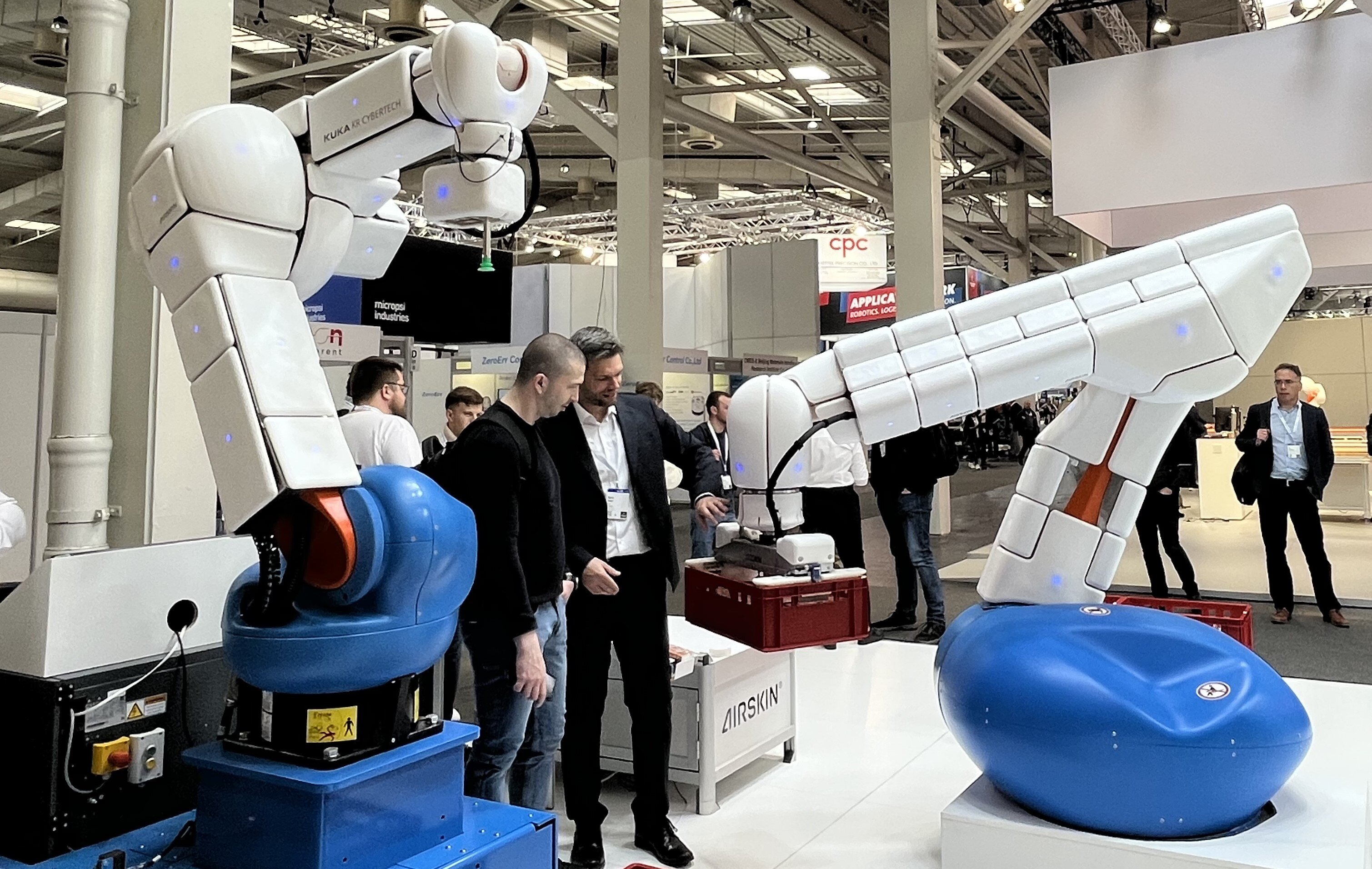

AIRSKIN Safetyflange

A collision sensor for end effectors, tools and workpieces

Your needs:

- Protection for your gripper and workpiece

- Full safety for your workforce

- Limited speed in collaborative robots

AIRSKIN offers:

- AIRSKIN Safetyflange is the perfect safeguard for the EoAT and Workpiece

- CE marked and certified with PLe/Cat.3

- With AIRSKIN Safetyflange you can speed up to 2 m/s

What is an AIRSKIN Safetyflange? And how does it work?

The AIRSKIN Safetyflange is a coupling between the robot arm and the end effector, enabling fenceless applications by securing the tool and workpiece. This electromechanical collision sensor is based on the pressure sensitive AIRSKIN technology (PLe/Cat3 ISO 13849-1).

It activates a safety stop through tilting, twisting (torsion), or translation in the z-direction. The forces can be adjusted according to application needs, and it offers automatic reset with high precision. Any displacement of the AIRSKIN Safetyflange immediately triggers an emergency stop.

Advantages of AIRSKIN Safetyflange:

- Adjustable Trigger Force in all directions

- Eliminates pinch and crush risk ("Finger-Safe applications") in accordance with ISO/TS 15066

- High reset accuracy for industrial applications

- Standardized mechanical interface (ISO 9409-1)

- Highest safety standard: PLe/Cat3 (ISO 13849-1) or SIL 3 (IEC 62061)

Safetyflange enhances the safety and efficiency of fenceless industrial robot operations where human and robots collaborate or where delicate tasks require precise force control.

AIRSKIN Safetyflange Series

AIRSKIN has developed a range of Safetyflanges, each engineered to operate with the same safety standards. Understanding that every application has unique requirements, we have designed each Safetyflange to meet specific needs for payload capacity and adjustable forces in various directions.

Explore our selection of four different types of AIRSKIN Safetyflanges, each offering the same level of safety assurance with unique mechanisms:

- AIRSKIN Safetyflange 10: Payload up to 10 kg with 5 different springs to adjust the actuation force as needed

- AIRSKIN Safetyflange Pro: Payload up to 15 kg with 3 different magnet magazines and the ability to add or remove magnets from the translational magazine

- AIRSKIN Safetyflange Pro Core: the same as AIRSKIN Safetyflange Pro but without AIRSKIN-Pad

- AIRSKIN Safetyflange 20: Payload up to 20 kg with 3 different springs and the ability to adjust the magnetic force

Easily customize the forces of the Safetyflange to suit your needs with minimal effort.

Speed

Up to 6 times faster than comparable fenceless/collaborative solutions on the market

Flexibility

Fits any robots and mounted directly onto the robot for flexibility in location and task

Space

Removing fences and light curtains saves up to 90% of floor space than can be used otherwise

Safety

Safeguard for the tool and Workpiece. PL e, Cat.3 / SIL 3 certification guarantees the highest safety standard for collaborative robots

We provide help to get the ideal AIRSKIN Safetyflange that fits your application

Just like any other product on the market, selecting the ideal fit for your application involves considering specific points. We're delighted to guide you in choosing the perfect Safetyflange from our extensive product range. To do so effectively, there are some key details we need to understand upfront:

- Information about tool and workpiece:

- Weight (Individual and Total)

- Center of Mass (Individual and Total)

- Screenshot, CAD, photo or video

- Information about application:

- Cycle time

- Travel motion

- Workpiece handling/deposition

- Required absolute accuracy

Advantages of having AIRSKIN as your Partner:

Care free solution

The AIRSKIN team can consult you, help you building your application or offer you the full care-free package for your Pick & Place application, even with a signed CE-marking.

Safety by the experts

With decades of experience in fenceless industrial automation and a CMSE (Certified Machinery Safety Expert) in every project, we guarantee the leading edge of safety Know-How.

Strong network

AIRSKIN is not only part of leading networks (VDMA, A3), but also cooperates with international certification bodies (TÜV, UL, CSA) and with brand names (SICK, Pilz, Keyence, …)

AIRSKIN Safetyflange 10

The AIRSKIN Safetyflange 10 is primarily designed for pick-and-place applications, effectively minimizing crushing risks when setting down and moving a workpiece.

Before using the AIRSKIN Safetyflange 10, a risk assessment will be conducted (ISO 12100), including measuring the corresponding biomechanical limits.

Advantages:

- Lightweight

- Compact design

- Compliant to ISO/TS 15066

- Trigger force adjustment with spring

Ideal for applications such as:

- Quality Control

- Pick and Place

- Gluing

- Machine Tending

AIRSKIN Safetyflange Pro/Pro Core

The AIRSKIN Safetyflange Pro is the most versatile safety system for tool and workpiece possible. Powered by the AIRSKIN technology, it comes in two versions: with additonal AIRSKIN Pad or without as Core-version.

The AIRSKIN Safetyflange Pro can be used in various applications where the tool, workpiece or both have to be protected regarding collisions with workers or objects.

Advantages:

- Forces adjustable with magnets:

- Decoupled mechanisms for different directions

- Good load-to-weight/dimension ratio

- Optionally without AIRSKIN Pad

Ideal for applications with complex movements:

- Pick and Place

- Machine Tending

- Palletizing

- Gluing

- Visual Inspection

- Assembly

AIRSKIN Safetyflange 20

AIRSKIN Safetyflange 20 is the biggest Safetyflange in the portfolio and supports up to 20kg of dynamic payload. AIRSKIN Safetyflange 20 monitors the displacement of a tool or workpiece in x, y and z direction as well as torsion around the z-axis.

AIRSKIN Safetyflange 20 is particularly suitable for implementing safe pick-and-place applications or other straightforward manipulation applications.

Advantages:

- Tilting force independently adjustable via magnet.

- Highest load capacity with 20kg

- Additional spring replacement

Ideal for applications with high accelerations:

- Machine Tending

- Palletizing

- Assembly

- Pick and Place