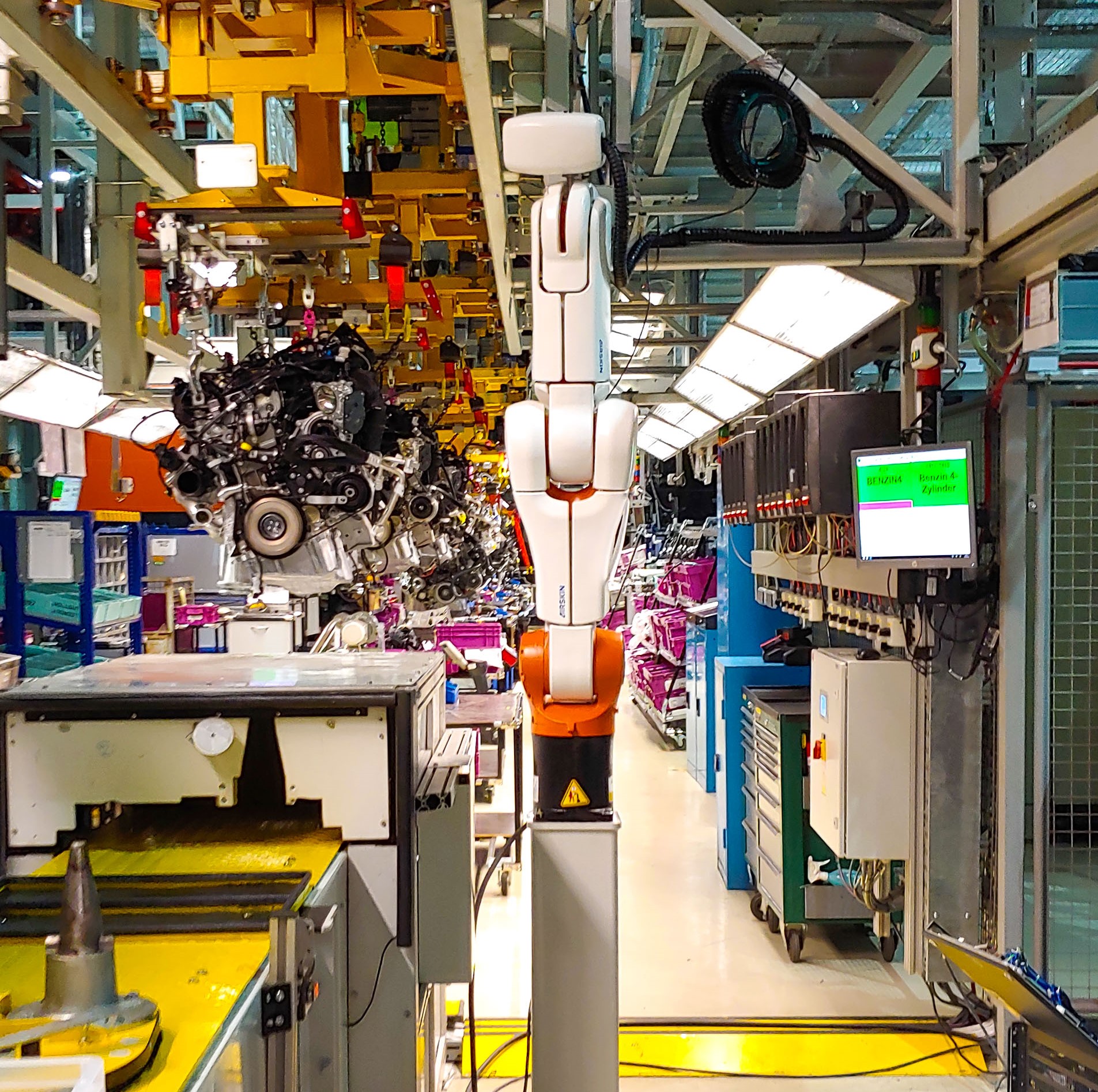

AIRSKIN in

Mechanical Engineering

Your problems:

- Not enough space for a fenced cell

- Precision of industrial robots needed

- Heavy weight

- Full safety for the workforce is necessary

AIRSKIN solution:

- Automation on a 1 m² footprint

- Industrial robot precision

- Payload up to 300 kg

- CE marked and certified with PLe / Cat.3

Industrial automation is now essential across all sectors due to its ability to enhance efficiency, quality, cost-effectiveness, and adaptability in manufacturing processes.

However, conventional automation systems often have limited flexibility, and need extensive space for protective equipment. With AIRSKIN, these limitations are a thing of the past. Fenceless production with AIRSKIN enables an open and flexible industrial automation.

More about AIRSKIN technology

Your benefits with AIRSKIN applications in Machine Construction industry:

Speed

Up to 6 times faster than comparable fenceless/collaborative solutions on the market

Flexibility

Mounted directly onto the robot for flexibility in location and task

Space

Removing fences and light curtains saves up to 90% of floor space than can be used otherwise

Safety

PL e, Cat.3 / SIL 3 certification guarantees the highest safety standard for collaborative robots

Fenceless industrial robots with AIRSKIN - Combining the best of two worlds: Upgrading industrial robots to high performance, fenceless collaborative robots. With AIRSKIN, industrial robots can operate with full safety measures in place, eliminating the need for protective fences.

- Payload: Up to 300 kg

- Reach: Up to 3.1 m

- Tools: Can be built by the AIRSKIN team, by your team, or a combination of both

- CE-Marking: The AIRSKIN safety team can help you with your safety and even sign a full EC declaration of conformity

- Mobility: Fixed / Semi-mobile / Mobile

AIRSKIN and KUKA:

- KUKA Agilus: up to 10 kg and 1.1 m

- KUKA Cybertech: up to 24 kg and 2 m

- KUKA Iontec: up to 70 kg and 2.5 m

- KUKA Quantec: up to 300 kg and 3.1 m

AIRSKIN and Stäubli:

- TX2-60 series: up to 4.5 kg and 0.9 m

- TX2-90 series: up to 10 kg and 1.45 m

AIRSKIN and Epson:

- Scaraflex: up to 6 kg and 0.7 m

No matter the application complexity or tool size, even in limited space, we've got you covered. In addition to our standard products, we offer customized solutions designed specifically for your needs.

From concept to implementation, we collaborate closely with you to ensure that our solution matches your requirements, delivering optimal performance in your production process. Our fenceless experts ensure that our solutions meet safety standards and machinery guidelines.

More about AIRSKIN technology

Safety

With decades of experience in fenceless industrial automation and a CMSE (Certified Machinery Safety Expert) in every project, we guarantee the leading edge of safety Know-How.

Programming

The AIRSKIN application team works together with all robot and control manufacturers. They can program all mayor robots and controllers on the market.

Tools

Assembly often needs tools, grippers and fixtures specially designed to your tasks The AIRSKIN team can help you with consulting, concepts and fully taking care of all necessary parts.