ROI Calculation

Cost leadership with AIRSKIN

Your problems:

- High costs for fence construction

- Long ROI times for security investments

- Limited revenue growth from safety measures

AIRSKIN solution:

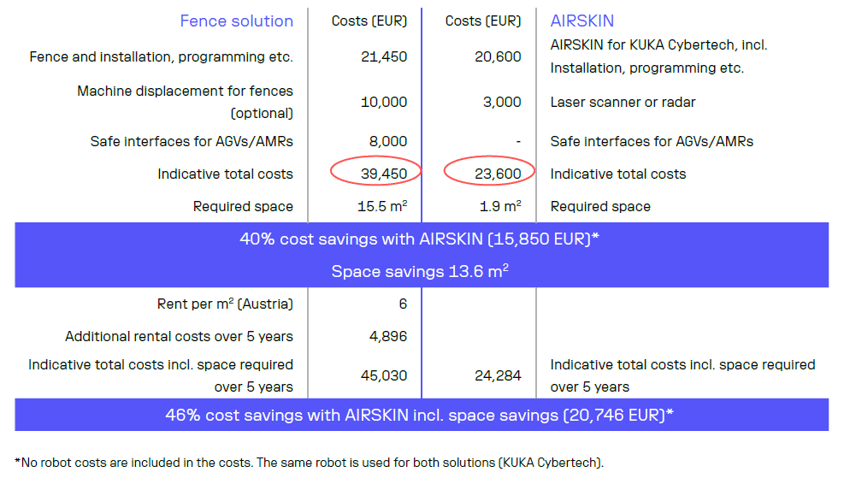

- 46% cost savings compared to fence solution

- ROI within 6-12 months

- Sales revenue increase of 3 mio. EUR and more per year

Quantitative cost savings

AIRSKIN vs fence

Lowering of investment costs

AIRSKIN requires less programming effort and offers inherent safety, which saves costs and avoids additional complexity when using AGVs and AMRs.

Lowering of opportunity costs

AIRSKIN saves space by being mounted directly on the robot, offering up to 90% space savings and allowing the customer to free up several hundred square meters in the factory, which can be used for other productive purposes.

Lowering of operative costs

AIRSKIN solutions reduce costs through flexibility, avoid additional safety costs during layout changes, and enable industrial robots to safely handle payloads of up to 300 kg.

Increase of Output

Industrial robots with AIRSKIN are up to 6 times faster and safer than cobots, can handle payloads of up to 300 kg, and significantly increase output, especially in 24/7 operations.

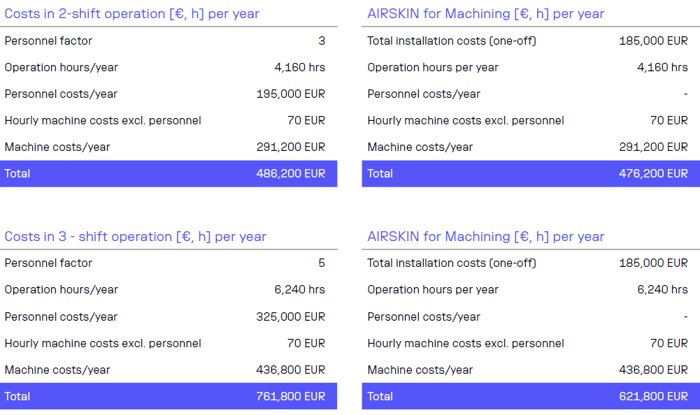

Output advantage - increase in revenue

AIRSKIN with industrial robots vs production without robots

As an example here we show a company in the metalworking industry. It wants to transit from pure manual operation to automation with robots. We considered 2-shift operation as well as 3-shift operation.

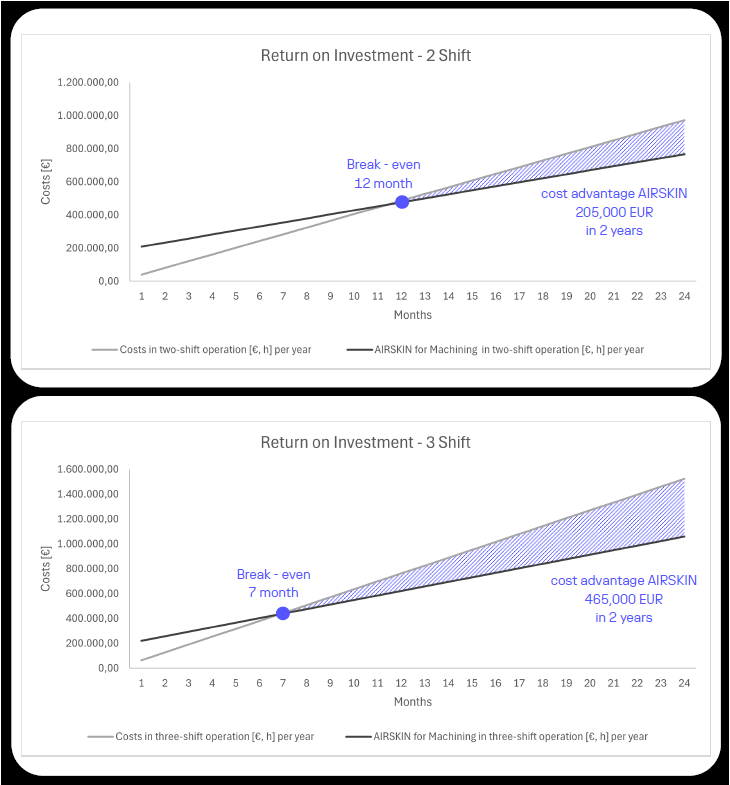

ROI

From those specific parameters we get a ROI (Return On Investment) of under 12 months for the 2-shift operation. For the 3-shift operation the result is even better. Here break-even is reached within 7 months.

Our experience shows, that with most applications that are implemented with AIRSKIN the return on investment is between 6 - 12 months, in some special cases even within 3 - 6 months.

Output advantage - increase in sales

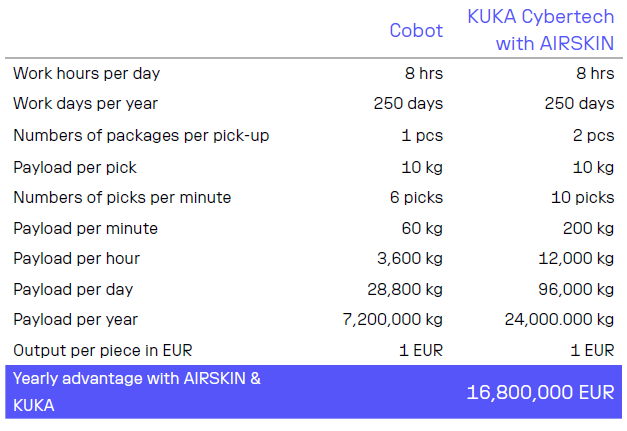

AIRSKIN vs Cobots

Below you can see an example from the industry, that shows the economic advantage of AIRSKIN solutions versus cobots. In this case we look at a palletizing and depalletizing application.

Cobot palletizer for palettizing and depalletizing application.

Movable 6-axis-robot for Human-Machine- Cooperation, the bigger version for dynamic palletizing & depalletizing. This application with AIRSKIN brings a revenue advantage of over 16.8 Mio EUR.

More about AIRSKIN technology