Optimizing cosmetics production with AIRSKIN®

The market for beauty and cosmetic products is challenging and intense. Therefore, it is necessary to optimize your production cycle for economic success. The last years, however, showed that especially in the cosmetic industry the need for modernizing the production process has heavily increased. It happens quite often that production sites are restricted due to space and run at full capacity. In addition, many products in the cosmetic industry are made in different versions.

Usually, the packaging is delivered in an unstructured way, just think about the numerous bottles and closing caps for shampoo and shower gel. The various products require a flexible change of formats. And finally, precise, and exact manufacturing is an absolute must, like scratches or other visual damages to the packaging directly influence the image and the value of the whole product.

The automation process between humans and robots requires a completely structured production system!

Our solution:

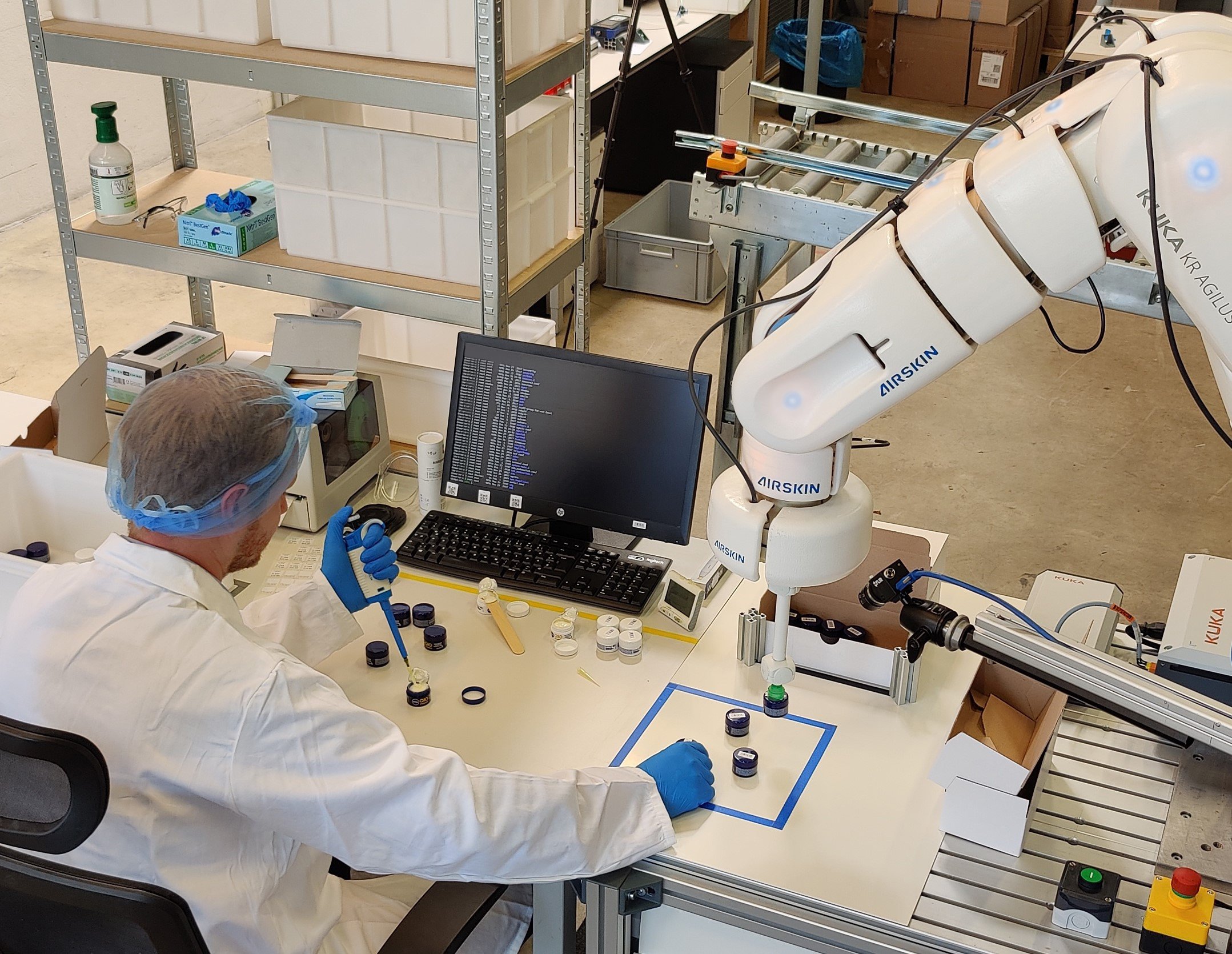

With AIRSKIN® you can easily integrate collaborative applications with precise and high-performance industrial robots into the production process – no fences are required anymore! So you are able to modernize your production line, automate your various production cycles and use the existing floor space efficiently – at the highest level of safety!

Interesting applications are also offered by AIRSKIN® in connection with decoupled production, as the focus lies in optimizing the logistic chain. Shampoo bottles, for example, are filled, then stored at the warehouse, and later on, in a second step, labeled and packed. A combination of a robot with AIRSKIN® and an AGV (Automated Guided Vehicle) will handle the necessary production steps.

AIRSKIN® is certified by TÜV Austria in accordance with ISO 13849 and reaches the highest safety category PLe 3, Kat.3.

For more information please contact our sales team!