AIRSKIN

Quality Control applications

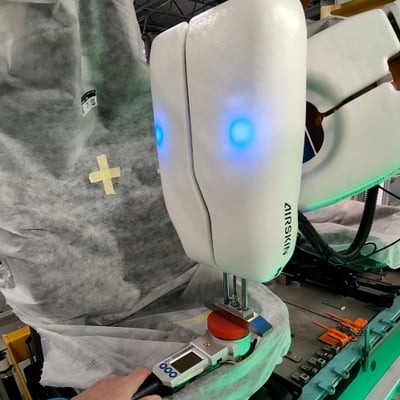

Success Story: In-line car seat measurement at BMW Regensburg.

No Fences. Highest speed. Highest safety. Shortest ROI.

Your problems:

- Necessary time-consuming quality control steps

- Not enough space for a fenced cell

- Precision of industrial robots needed

- Full safety for the workforce is necessary

AIRSKIN solution:

- Automated quality control without cell

- Industrial robot precision

- Automation on a 1 m² footprint

- CE marked and certified with PLe / Cat.3

Automate quality control right where it is needed instead of bringing the products to the control cells

No matter the product and no matter the space requirement: The AIRSKIN Fenceless Experts build your fenceless quality control application for your product directly into your production depending:

- Payload: Up to 300 kg

- Reach: Up to 3.1 m

- Tools: Tactile or camera - the AIRSKIN team can take care or work together with your specialists

- CE-Marking: The AIRSKIN safety team can help you with your safety and even sign a full EC declaration of conformity for your application

- Mobility: Fixed / Semi-mobile / Mobile – Depending on your tasks, the robot can stay at the same place or change place

More about AIRSKIN technology

AIRSKIN Quality Control applications currently can be realized with:

AIRSKIN and KUKA:

- KUKA Agilus: up to 10 kg and 1.1 m

- KUKA Cybertech: up to 24 kg and 2 m

- KUKA Iontec: up to 70 kg and 2.5 m

- KUKA Quantec: up to 300 kg and 3.1 m

AIRSKIN and Stäubli:

- TX2-60 series: up to 4.5 kg and 0.9 m

- TX2-90 series: up to 10 kg and 1.45 m

AIRSKIN and Epson:

- Scaraflex: up to 6 kg and 0.7 m

Tools for quality inspection:

Tactile measurement

Visual measurement

AIRSKIN Quality Control applications always contain the tools required for the task at hand. Regardless of whether it involves measurements with contact (tactile measurements) or measurements without contact (visual measurements): AIRSKIN's experts will help you with everything:

- Selecting the right measurement method

- Designing the quality control application

- Realisation of the application in your production

- Complete CE marking with all the necessary documentation

Automated Leak Detection (ALD-360) by Agramkow

More frequently changing product ranges, smaller batch sizes, increasing quality requirements and the shortage of skilled workers demand an automated solution for the quality control of copper tube joints.

A KUKA Agilus-2 with AIRSKIN, Safetyflange 10 and a special 360° leakage-tool mounted onto a movable trolley with a specialized software suite by Agramkow.

More about AIRSKIN technology

Your benefits with AIRSKIN Quality Control applications:

Speed

Up to 6 times faster than comparable fenceless/collaborative solutions on the marketFlexibility

Mounted directly onto the robot for flexibility in location and taskSpace

Removing fences and light curtains saves up to 90% of floor space than can be used otherwiseSafety

PL e, Cat.3 / SIL 3 certification guarantees the highest safety standard for collaborative robots