AIRSKIN

Palletizing applications

Your problems:

- Human workers still palletize manually

- Not enough floor space for fenced automation

- Rather simple repetitive tasks done by humans

- Full safety for the workforce is necessary

AIRSKIN solution:

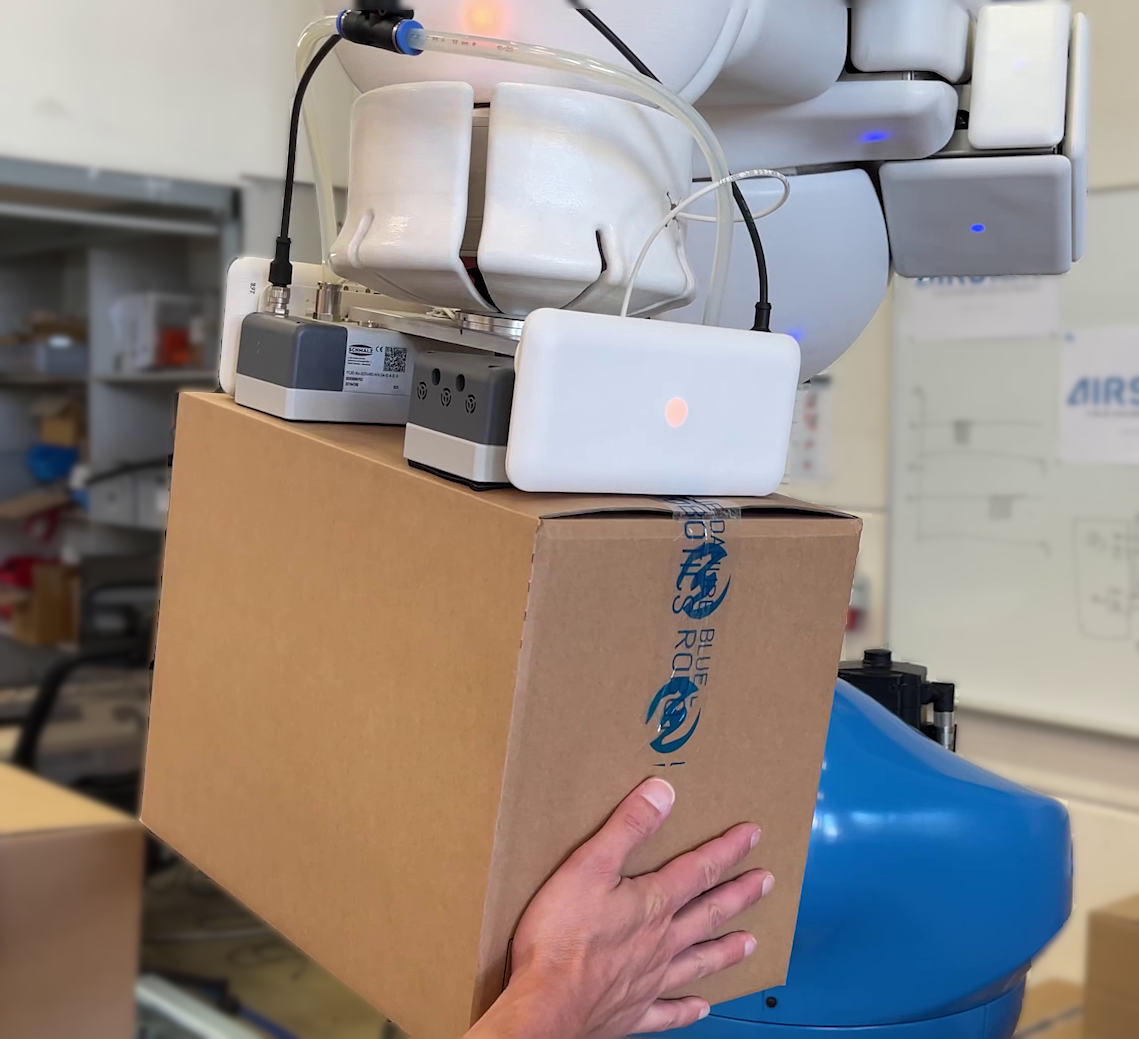

- Fenceless AIRSKIN palletizing robot

- Up to 300 kg payload and 3 m reach

- End of line palletizing without fences

- CE marked and certified with PLe / Cat.3

Flexible palletizing solutions for every payload.

High speed. Safety certified.

AIRSKIN and Cybertech

Only solution in the market to palletize with high speeds up to 2 m/s, up to 10 picks/minute or up to 20 kg parcels.

AIRSKIN and Agilus

This combination is the faster alternative to cobots for palletizing into KLT boxes (Euro container).

AIRSKIN and SCARAFLEX

The fastest and most cost-effective solution to palletize light parts from and onto trays using a Scara robot.

Solving your palletizing challenges with AIRSKIN

We cover the robot and gripper with a soft, safety-certified skin. Compliant with ISO/TS 15066 safety requirements regarding collisions, crushing & shearing. Providing you with a completely safe open format work environment for your palletizing operation.

No fence or laser scanner required.

More about AIRSKIN technology

Your benefits with AIRSKIN Palletizing applications:

Speed

Up to 6 times faster than comparable fenceless/collaborative solutions on the market

Flexibility

Mounted directly onto the robot for flexibility in location and task

Space

Removing fences and light curtains saves up to 90% of floor space than can be used otherwise

Safety

PL e, Cat.3 / SIL 3 certification guarantees the highest safety standard for collaborative robots

AIRSKIN Palletizing applications currently can be realized with:

AIRSKIN and KUKA:

- KUKA Agilus: up to 10 kg and 1.1 m

- KUKA Cybertech: up to 24 kg and 2 m

- KUKA Iontec: up to 70 kg and 2.5 m

- KUKA Quantec: up to 300 kg and 3.1 m

AIRSKIN and Stäubli:

- TX2-60 series: up to 4.5 kg and 0.9 m

- TX2-90 series: up to 10 kg and 1.45 m

AIRSKIN and Epson:

- Scaraflex: up to 6 kg and 0.7 m

AIRSKIN Safetyflange - robotic collision sensor

The special Safetyflange for palletizing is based on the AIRSKIN technology. The Safetyflange protects the EoAT and reduces the risk of damage when picking up new objects. It also protects people from potential pinching hazards when placing objects. This also can be used to protect sensitive end of arm tooling configurations or expensive material you are handling.

Safetyflange complies with the PLe / Cat. 3 ISO 13849 safety certification.

More about AIRSKIN technology

Features of working with the AIRSKIN team:

Strong network

AIRSKIN is not only part of leading networks (VDMA, A3), but also cooperates with international certification bodies (TÜV, UL, CSA) and with brand names (SICK, Pilz, ...)

Care free solution

The AIRSKIN team can consult you, help you building your application or offer you the full care-free package for your alletizing application, even with a signed CE-marking.

Safety by the experts

With decades of experience in fenceless industrial automation and a CMSE (Certified Machinery Safety Expert) in every project, we guarantee the leading edge of safety Know-How.