AIRSKIN

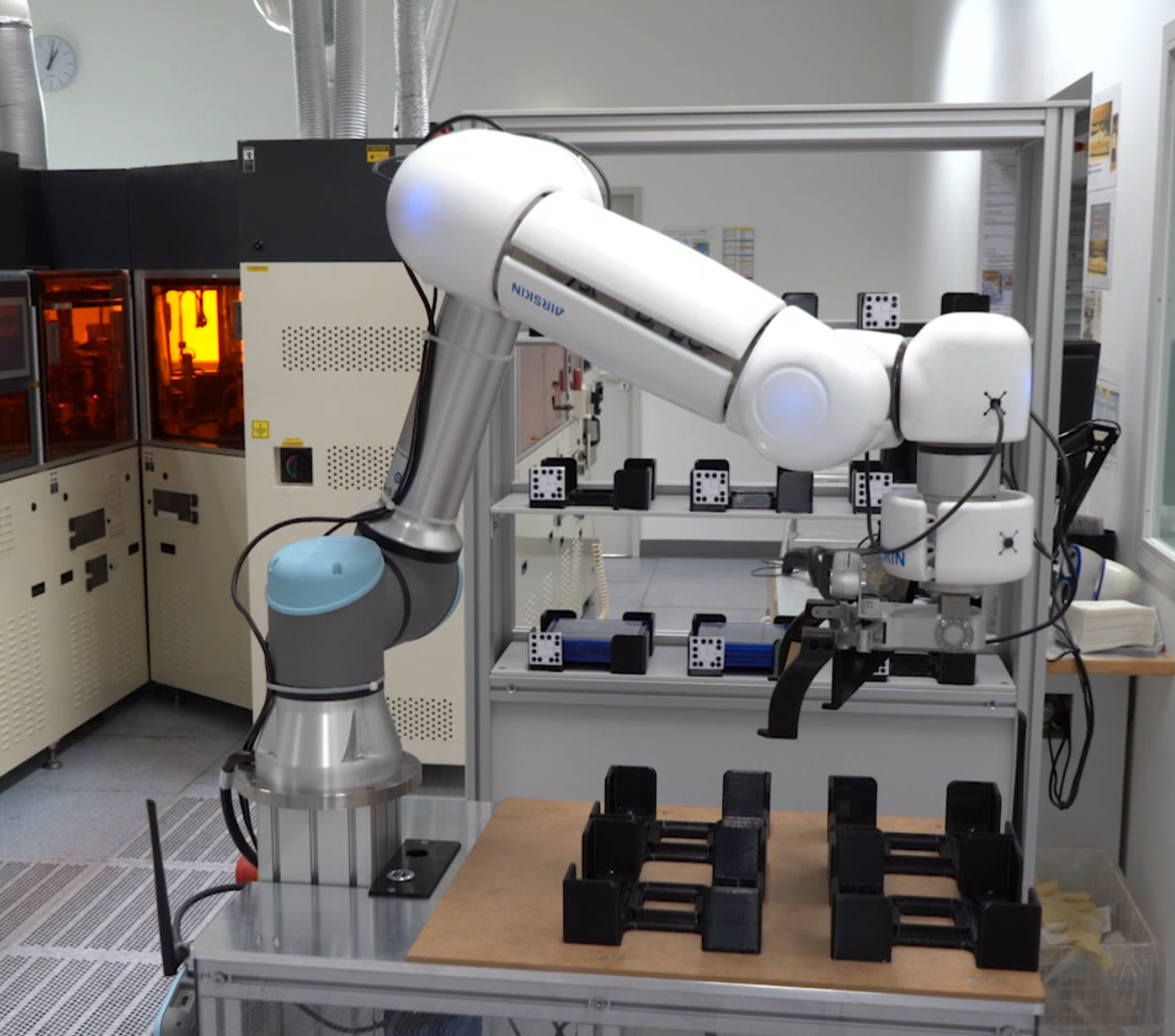

Machine Tending applications

Industrial robots tending to your production machines without changing your whole layout.

Smallest footprint. Highest safety. Highest speed. Shortest ROI.

Your problems:

- Machines that need to be assisted

- Not enough qualified workers and repetitive tasks

- Not enough floor space for automation

- Full safety for the workforce is necessary

AIRSKIN solution:

- Fenceless AIRSKIN industrial robot

- Automation on a 1 m² footprint

- Assistance for your existing machines

- CE marked and certified with PLe / Cat.3

AIRSKIN Machine Tending applications for your existing production

The AIRSKIN Fenceless Experts build your personalized fenceless machine tending application directly into your production depending on your needs:

- Payload: Up to 300 kg

- Reach: Up to 3.1 m

- Tools: Can be built by the AIRSKIN team, by your team, or a combination of both

- CE-Marking: The AIRSKIN safety team can help you with your safety and even sign a full EC declaration of conformity

- Mobility: Fixed / Semi-mobile / Mobile

More about AIRSKIN technology

Your benefits with AIRSKIN Machine Tending applications:

Speed

Up to 6 times faster than comparable fenceless/collaborative solutions on the marketFlexibility

Mounted directly onto the robot for flexibility in location and taskSpace

Removing fences and light curtains saves up to 90% of floor space than can be used otherwiseSafety

PL e, Cat.3 / SIL 3 certification guarantees the highest safety standard for collaborative robots

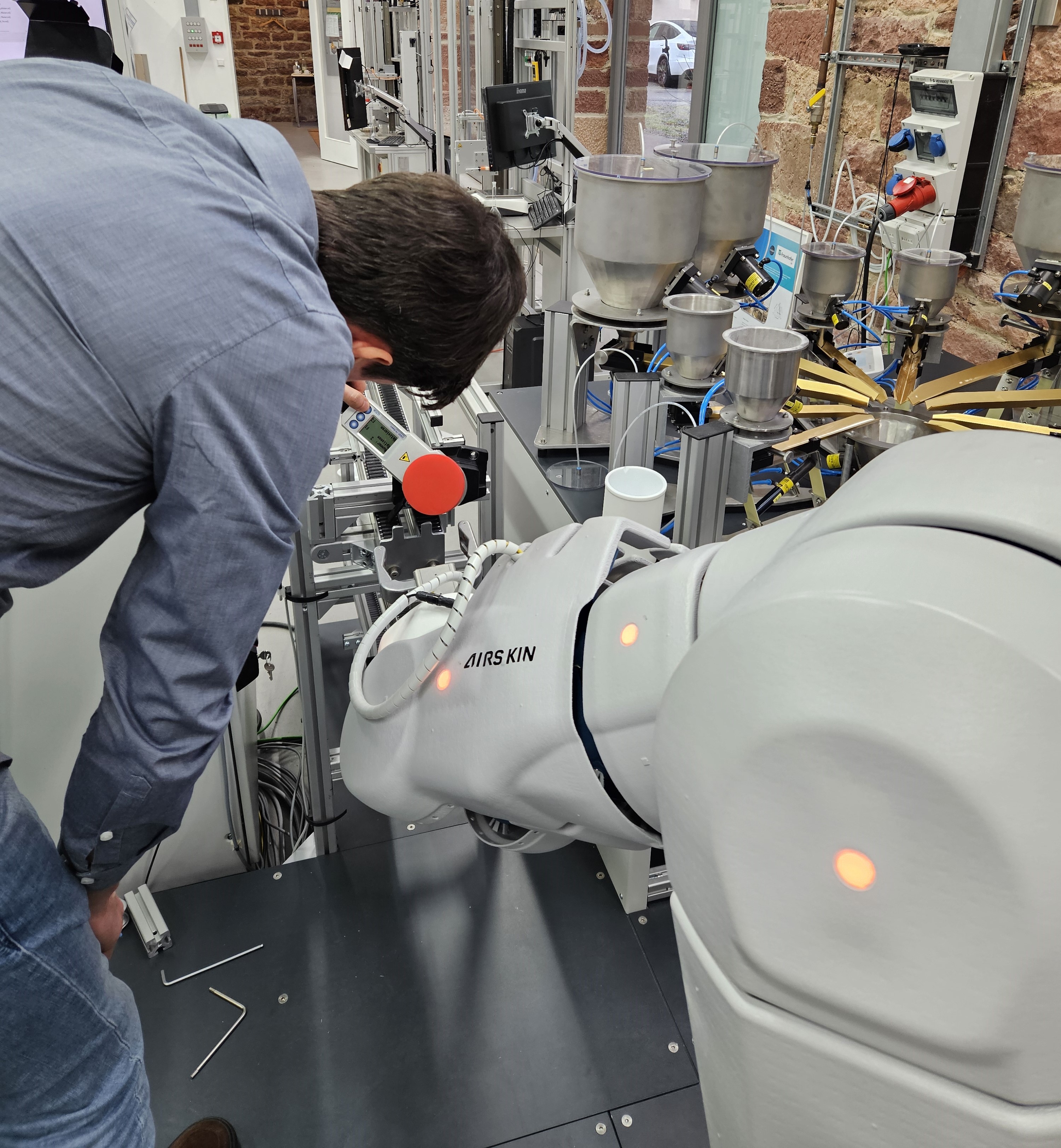

The best of two worlds in your production

The AIRSKIN Fenceless Experts can realize your machine tending applications by combining the best of two worlds. They take all the benefits of industrial robots: speed, precision, payload, reach and durability, and combine them with the benefits of collaborative robots: flexibility, easy set-up and no fences. With this combination they build productive fenceless applications that make your machine shop fit for the future.

All your machine tending solutions, independent of part size and weight, can be realized in your existing production without the necessity of annoying fences.

More about AIRSKIN technology

AIRSKIN Machine Tending applications currently can be realized with:

AIRSKIN and KUKA:

- KUKA Agilus: up to 10 kg and 1.1 m

- KUKA Cybertech: up to 24 kg and 2 m

- KUKA Iontec: up to 70 kg and 2.5 m

- KUKA Quantec: up to 300 kg and 3.1 m

AIRSKIN and Stäubli:

- TX2-60 series: up to 4.5 kg and 0.9 m

- TX2-90 series: up to 10 kg and 1.45 m

AIRSKIN and Epson:

- Scaraflex: up to 6 kg and 0.7 m

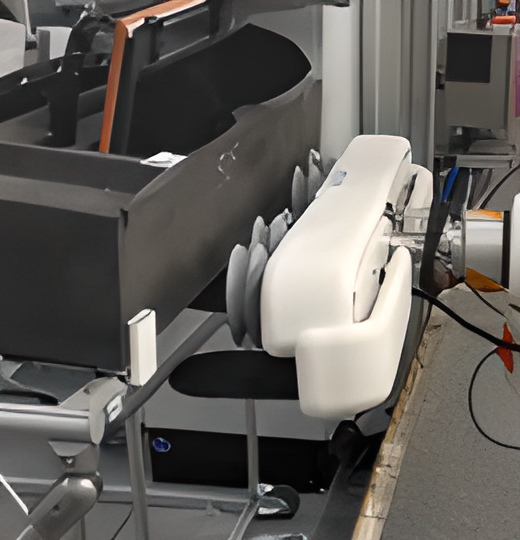

The right tool for the right machine tending

No matter the machine that needs tending to and no matter the product – the Fenceless Experts of AIRSKIN can help you get the right tool for the task. If a tool/gripper is built for a fenceless application starting at the concept phase, safety is not an issue and the benefits of an open and flexible application can be realized even more.

The modular AIRSKIN technology is perfect for designing and building EoATs (End of Arm tools) for fenceless applications.

More about AIRSKIN technology

The AIRSKIN offering:

One-stop shop

You get a tailored application into your production by the AIRSKIN Fenceless Experts. They can consult you, help you building your application or offer you the full care-free package, depending on your choosing.

Specialized tools/grippers

Machine tending often needs grippers specially designed for your products. The AIRSKIN team can help you with consulting, concepts and even fully taking care of the necessary grippers and tools.

Expert Safety

With decades of experience in fenceless industrial automation and a CMSE (Certified Machinery Safety Expert) in every project, we guarantee the leading edge of safety Know-How.